(with separate grinder,

forge/anvil, and

power hammer sections)

(with separate grinder,

forge/anvil, and

power hammer sections)

Tools and shop information: (with separate grinder,

forge/anvil, and

power hammer sections)

(with separate grinder,

forge/anvil, and

power hammer sections)

![]() Please

read this link:

Safety concerns for knifemakers

Please

read this link:

Safety concerns for knifemakers

![]()

Health hazards associated with welding/high heat

Dealing with static shock from machinery

Here are some ideas for a basic bladesmithing set up.

Setting up shop (anvil, forge and post vise)

Tutorial on Measurement and Layout

MrTitanium Presents: How to build an anodizer for chump change

Anvils:

Bandsaw Meltdown - Fire Hazard!

Portable band saw information (more info here, with mounting ideas)

Home made Soldering Station Venting System

Just a couple of more broaches

Charts, Tables and Conversions:

Brinell and Vickers Hardness Scale and Tensile Strength Comparison Chart

Pulley And Belt Information Calculator

Steel Chart, Conversions, Useful Charts, Links

Surface Speeds from wheel dimensions and RPM

Temperature conversion calculator

Tolerance Charts: Standard Shaft - Hole Fits

http://metalwebnews.com/ed.html - THE METAL WEB NEWS EDUCATIONAL & REFERENCE PAGE

Creating Large Diameter Holes Using Small Diameter Drills.

Calculator for creating Large Diameter Holes Using Small Diameter Drills.

Keyway Depth Information.

Cutting Depths for Woodruf Keys.

Machine Screw Drill Tables for Tap Sizes and Clearance Holes.

Locating Center Distances for Holes.

Conversion Tables Wiha Tools.

Science & Engineering Encyclopedia Science and engineering descriptions, equations, conversions, calculators and material data. Organized by A to Z, subject and interlinked.

Metric Conversion Table - Metric Conversions, Explanation and history of the metric system.

Drill chart – decimal equivalents. pipe tap sizes, and drill tap sizes

Cyclone Dust Collector Research

Five Minute Paint Booth (might be a solution to grinding dust)

Homemade Cyclone Dust Collection System

Build your own electro-chemical marking device

Electro-etching logos:

Build your own electro-chemical marking device

Etching Tutorial and Etching Supplier Listing by Tracy Mickley

Help/tips on stencils and etching

Electric motor control information

How to set up for variable speed on a "Shoestring Budget "

Lesson variable speed motor adjustments

Lessons on electrical circuits

Phase converter information

The Selection, Connection, Reversing and

Repair of Electric Motors

File Guides and File Jigs -- A Primer...

Hints and Tricks on using File Guides and File Jigs...

Make a "Small Screw" Holder for Filing or Grinding

Forges:

Epoxies: Glue Wars - the battlefield is set

Lessons learned from the "Glue Wars" (also see the "Spread sheet" link near the bottom)

Loctite Xtreme Repair Adhesive

Grinders:

See "Grinders" section below.

Build your own Hardness Tester!

File Guides and File Jigs -- A Primer...

Grinding jig by Filip De Coene, knifemaker

Knife bevel grinding jig (using an angle grinder) – Langdon Wilson, Knifemangler

Steve Bedair's 9 x 20 Lathe Site

Simple, easy to make stitching pony

Machinist's Miscellaneous Information

Miscellaneous shop related links

Metalsmithing - "how to" articles 8-6-2006 This site has dropped a lot of articles. Hopefully they will be put up again.

The Advanced Machinist, a practical and educational treatise, with illustrations.

Marking; stamps, gravers, etching machines:

Custom tang stamps - Henry Evers

Custom knife stamps - Harper mfg.

Tools made from nails - graver and punch

Building

An Electro-Etching Unit ![]()

![]()

![]()

![]()

![]()

Etch-O-Matic (electro-chemical marking)

Mill:

Device for slack belt grinding on 4" x 36" machines

How to Hot Blue you Knife Blades For Less than $75.00 By Wil Hurley

Site with a lot of photos/info about machinery/tools used by blacksmiths (many homemade)

Controller package for knifemakers

Homebuilt heat treatment oven (.pdf)

Homemade oven/kiln (more info), (even more info)

The New and Improved Lil' Bertha

Digital Photography How-To: Building a Light Tent

'No Frills' $75.00 home studio tent/lightbox

Photo Studio at home - The Rubbermaid diffuser

Power hammers:

see "Power hammers/presses information"

Also see "Power hammers/presses information"

Chris Crawford also has one on his site.

Todd Briggs's bottle jack press

20 Ton Hydraulic Press plans for sale

Electrolytic method of rust removal

More on salt pot design by J. Loose - (use the "Studio" link)

Salt pot controller information

Gaijin's Guide's Sanding Block System

Hand rubbing being a pain? can't get the flats as smooth as you want? Try this trick - palm sander with micarta plate

A Workers View on Stabilization

Nelsonite 30B02 Wood Stabilizer

It is ALIIIVEEE......Jens Anso’s homemade surface grinder

Numbering system for welding electrodes

US Army Theory of Welding and Application.pdf

Build Your Own Advanced Jewelers Bench

Build Your Own Basic Jewelers Bench

http://www.cs.wisc.edu/~bolo/workshop.html - Bench Makers and Plans and Notes (from a woodworking, but still applicable)

Bill's Claspy's Workbench -- inspired by Good, Fast, Cheap Bench

Building a Traditional Workbench

A Gallot and his shop (Klausz Bench)

Jeff Greef -- Wooden Vises from Scratch

Larry McVoy's workbench with combination end/tail vise

Parts for Scott Landis / Michael Fortune Tail Vise

WoodVise -- Shoulder, Front, Tail all in one!

Workbenches .. many designs, building shoulder vises

Work Bench Designs -- A resource for woodworkers

Grinder

information:__________________________________________________

![]() Please

read this link:

Safety concerns for knifemakers

Please

read this link:

Safety concerns for knifemakers

![]()

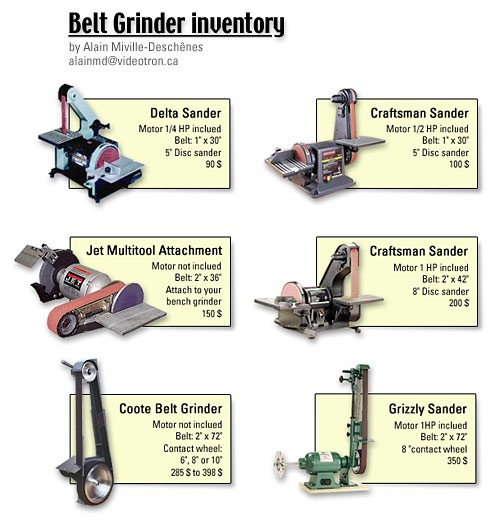

Photos of some commercial grinders that are available.

(courtesy

of Alain Miville-Deschenes;

http://www.amd.miville-deschenes.com)

Grizzly grinder - Search "G1015" - This is the baseline 2" x 72" entry level machine. It will need some work to the platen and it is difficult (but not impossible) to do hollow grinds with the stock 8" wheel because of motor clearance issues. If interested, WAIT FOR IT TO GO ON SALE. This happens about twice a year and is a much better deal. (see Modifications for the Grizzly G1015 grinder for improvements or "Tracking the Grizzly" to resolve tracking issues)

Herbst Knifemaking machines -

Machines designed to enhance

and combine the functionality of Batavia Engineering’s famous Cutlermatic, Mini-Cutlermatic

and Discmatic

"Homemade" grinders ;

photos, building info, and many links ![]()

![]()

![]()

![]()

![]()

KMG grinders (also see: "The KMG grinder. my assessment and thoughts " by Ed Caffery and MAP (Multi Articulated Positioning) Arm for KMG Belt Grinder - Discussion and more photos here.)

Knut Lie (contact info) He now has a website; see the Suremak link below.

Ovation belt grinder - Japanese page; Translator (cut and paste the url; use the lower set of characters in the url drop down box for English)

Pro Cut II grinder May no longer be available 1-22-2007

Simplatic Belt & Disc Grinder and Kit

Suremak Industries 2"x72" Knife Grinder

Wilton Square wheel grinder (also

see:

"Tricking out" the Wilton Square wheel

grinder" by Ed Caffery)

Wolfmaster grinder

Sando non-spinning rotary platen

Application chart and info on different abrasive sanding belts

Pulley And Belt Information Calculator

Surface Speeds from wheel dimensions and RPM

Discussion

on the merits of the higher end grinders

![]()

![]()

![]()

![]()

![]()

Some thoughts on grinders

(as found on various knife related forums):

This is

Ed Caffery's

response to the question "... would one of those little Delta 1x42

belt/disc grinders get me by for the first year or should I go ahead a buy

something like a multitool? ":

" The

cheap part of me says that the 1x42" grinder will work, but the other side wants

to tell you that if you can spring for a good 2x72" grinder, you'll never have

to buy another one, and your learning curve will be cut considerably.

I still own that first Wilton Square

wheel grinder that I purchased from Koval Knives....at that time it cost me $540

with shipping, brand new (guess it has been a while![]() ).

I've gone through a few contact

wheels, and a few bearings, but she works as well today, as she did out of the

box.

).

I've gone through a few contact

wheels, and a few bearings, but she works as well today, as she did out of the

box.

I think doing it by hand a few times

will render benefits too.

Remember, the machines won't do anything that you can't do by hand....all they

do is save time. If I remember correctly, the first dozen or so knives I

made were forged and finished all by hand."

_______________________________________________________________________________________________________

Craig Wilkins on the advantages/disadvantages of 2 and 3 wheel machines:

"I have noticed that some belt grinders have just 2 wheels while others have 3. What is the advantage of one over the other?

I will try to answer this one...

As stated, there are basically two types of grinders alluded to above, basically

the Burr King and Hard Core grinders are of the two

wheel variety, Rob Frinks's excellent KMG grinder and the Bader grinder

are of the the "three wheel" variety.

I have used at different times a Burr King, Wilton, Bader and a Hard Core, I own

a variable speed Hard Core grinder but to be fair and truthful about it, I

bought it before I ever used any of the others. The Burr King was/is not

available but is an excellent machine.

Two wheel setup - Burr King and Hard Core

Advantages:

Tracking is unsurpassed, smoothest machines on the market that I have used. Just

a dream to use.

Disadvantages:

1) Attachment setup takes a very long time. Five to ten minutes if changing from

the flat platen assy. to a hollow ground set up. (I may add that the flat platen

assy. makes this in essence a three wheel set up)

I have a 10 inch contact

wheel. When going from it to the flat platen assy., the idler

wheel had to be swapped out as well. The flat

platen assy. requires an 8 inch idler, the 10 contact

wheel requires a 6 inch idler. (Maybe THAT'S why

I don't hollow grind very often!)

2) The belt on these type grinders are driven off

of the contact wheel.

When changing contact wheels (4 inch for flat

platen assy., 8 or 10 inch or whatever for hollow grinding) the belt speed

changes. For example, the belt is A LOT slower for flat grinding. Let's just say

that the MAXIMUM speed is slower with a variable speed grinder when changing to

a smaller contact wheel.

How is this important? Slower speed equals slower grinding.

Three wheel grinders - KMG and Bader

Advantages:

1) Setup and assy. change out is a breeze, takes about 10 seconds max. (The flat

platen assy. makes this a 4 wheel grinder in

essence.)

2) Belt speed is constant - regardless of the assy. installed, it is driven off

of the same drive wheel.

Disadvantages:

1) Does not track as well as a two wheel set up.

Not as smooth.

From a personal perspective, if I were to buy another grinder after using some

of the others, it would either be a KMG or another Hard Core. With the Hard

Core, I would leave it set up in one set up only. This is the primary reason why

I have a separate small wheel setup opposed to

having the small wheel assy. that Hard Core has

to offer.

One thing that I have found. I am spoiled with variable speed. To anyone that is

in the market for a quality grinder, variable speed is worth every penny! From

final finish to sharpening.

Now, after stating all of that, a friend of mine made his own grinder using a

motor, round stock for the shaft, an idler assy he bought from one of the knife

supply houses, pillow block bearings and a 10" Burr King

contact wheel and is just as smooth as the

Hard Core grinder I have. He spent less than $500 on it. Other than it not being

variable speed, it is one of the finest setups I have ever seen. Granted, he

can't change set ups but it is as smooth as silk!"

_______________________________________________________________________________________________________

Ed

Caffery posted this on

contact wheel durometer:

"70 durometer is the standard that you will see on most commercially

available contact wheels. It's what comes as

standard equipment on all the usual grinders you see in a knifemaker's shop.

(Bader, Burr-King, Square Wheel, etc.)

Contact wheels are a double edge sword.... too

soft and it's easy to "wash out" your grind lines, and the

wheel edges will become rounded in very short

order. Too hard and the wheel leaves a terrible

finish (both referring to smooth wheels) With

serrated wheels, a softer

wheel will remove stock faster, but will wear down quickly, a harder

durometer serrated wheel

will take material off about like a softer smooth

wheel, but will last much longer and take much

more abuse.

Generally the 70 durometer is about normal for most knifemakers. Top end you can

achieve with most rubber compounds is 90 durometer. The rounding of corners

isn't a big deal because most of us will put a slight radius on the

wheel edges right out of the box.

I agree with Don, stay around 70 durometer max. and you'll be good all the way

around."

_______________________________________________________________________________________________________

Gene Osborne

on contact wheels: " Contact wheels are like tires

on a car. Most people won't know the difference but a "driver" will.

Wheels first have to be balanced. The faster they go, the more critical this

becomes. Unstable wheels WILL come apart.

Bearings or pillow blocks are needed if not mounted directly to the shaft.

Plastic is not a good choice especially for fast machines.

The face must be smooth and round. This can be trued once on the machine. If it

is not round, it will dig pits and ruts, bounce, and give poor grinds.

Hard face has no rubber.

Smooth face for finish grinding.

Serrated wheels for hogging metal.

Diameter controls the geometry of a hollow grind, most use large diameter wheels

to give a flatter appearance. I use a 6" wheel for most hollow grinding because

it gives a more dramatic hollow grind.

Lawn mower wheels are not recommended.

Casters can work, the best ones are from the medical world.

Most Americans don't mind driving on cheap tires, but the pro's want/need the

best.

If your grinder does 80% of your work for you, why skimp there?"

_______________________________________________________________________________________________________

Bob Warner

on

variable speed:

"When you are working your way down the list of grits during your knifemaking,

you will get down to the 400-600 grit range (and then even finer). At this fine

grit there are a couple of potential problems, first your metal can get real hot

real fast. If you are cleaning up a hardened blade, you can ruin the heat treat

and have to start over. Also, at a slow speed, your errors are not exaggerated.

If you accidentally make a mistake, it will be less of a mistake if the belt was

running slow (I know all about making mistakes, I must be an expert at it)."

_______________________________________________________________________________________________________

Ed

Caffery

on grinding belts

and backing materials:

"This is a response to a question from another

thread. I thought it might be of interest to many folks, so I started a new

thread with it in order to make it easy to locate.

Please add your inputs and experiences, these are my personal finding and

experience, and I'd be very interested to hear from others.

Different backings make a belt stiff or flexible, depending on the

type of backing, and I have found that the

backing material makes a big difference in the finish you get out of a

particular grit size.

For example, a "Y" weight backing is generally the thickest, stiffest backing,

and you find it mostly on the heavy grit belts (60 grit and larger) "Y" weight

belts don't like to bend around tight radius areas such as small

contact wheels. I have watched (and felt) the

grit tearing off of "Y" weight belts on contact

wheels of 3" diameter or less. On several occasions I have had brand new "Y"

weight belts break on startup when trying to use them on small

contact wheels because the backing doesn't want

to flex around the wheel, and the joint just

wouldn't take the stress. This weight backing is generally found on heavy grit

belts of 24-60 grit.

"X" weight is a bit lighter and more flexible, and is generally what I like to

use for my heaviest grit belts. It can make the bends around

contact wheels as small as 3/4" diameter

without much trouble. I've seen "X" weight backing on belts as fine as 400

grit, but don't like it in anything finer than 120 grit.

"J" weight is next in line, sometimes referred to as "J-Flex" backing, it is a

light weight backing that is very flexible. I like to use it on my finer grit

belts because I can track the belt out past the edge of the platen, and radius

out plunge cuts with it. (the backing will make a nice fine radius when it

wraps around the edge of the platen.)

"Mylar" backing is found on the 3M micron belts. It is a "plastic" material

that is very thin and light. It will easily flex around the smallest diameter

contact wheels, but does not flex well the

other direction (like around the edges of platens or

contact wheels) If you ever use this type

of belt, be VERY careful about getting your hands close to the edges of the

belt. It will cut you like a razor blade never even thought about! I've had

more than one trip to the ER to get sewn up from these belts.

I've been using Norton Norax belts for the past couple of years in X30, X22, &

X16 (400, 800 & 1200 grit) and really like the backing on these belts. I'm not

sure what to call their backing material....it's thickness seems to be

somewhere between an "X" and "J" weight, but is is much softer than either,

and very flexible. These belts seem to give a finish that is finer than the

same grits in other belts, and are so flexible that you can do just about

anything with them and they hold

together."

Forge/anvil

information:_______________________________________________

![]() Health

hazards associated with welding/high heat

Health

hazards associated with welding/high heat

![]()

Gas:

Building the Ron Reil style propane burner

Great forge info, including the mini forge and coffee can forge

Indian George's Forge building tutorial

JTH7 torch for use in the one fire brick forge

Melting & casting metal with homemade stuff and a tiny budget!

My Quick and Easy Propane Fired Forge

One

fire brick forge (background) and pipe forge

![]()

![]()

![]()

![]()

![]()

Plans of a Venturi Burner for Propane-Gas (PDF)

Ron Riel's site- great forge/burner information

![]()

![]()

![]()

![]()

![]()

Soft kiln brick heating chamber (forge)

Troubleshooting Your New Forge or Burner

Charcoal/coal:

Coal/Coke-forge, Several Designs & Ideas

How to Build a Forge for under $150

Primitive blacksmithing - drawing of a very simple sword forge. I've seen variations of this type of forge in different photos of primitive forges

The forge fire - scroll down

The Portable, Affordable Bobby's Forge!

Materials:

Refractory supplies - Ellis Custom Custom Knifeworks

![]()

![]()

![]()

![]()

![]()

Burner components and pipe fittings

Propane regulators and assemblies

Steel for knifemaking and damascus

Charcoal from the grocery store

Charcoal Making and Forging in the Japanese Tradition (pictorial)

Making Insulating Castable Refractory from common materials

Testing Refractories: Flux resistance

Anvil made from 2" steel plate

Build an anvil stand (,pdf)

Making a good inexpensive anvil

Using a sledge hammer as an anvil

Power hammer/press information:_______________________________________

http://www.beautifuliron.com/gs_air_hammers.htm - Forging Hammer References

Manufacturers & distributors of air hammers

Throttle stops for Chinese made hammers

http://www.iforgeiron.com/BPindex/Subject/Hammers/BPhammers.shtml#mechanical - I Forge Iron Blueprints; Subject - Hammers Site having problems as of 1-22-2007

http://magichammer.freeservers.com/ - Magic Hammer Forge

http://www.anvilfire.com/power/index.htm - Power Hammer Page

Catalog of User Built & JYH Hammers

Page 2 Niles-Bement Hammer

Page 8 Big

Boy Fly Presses

United Forging Hammers Beaudry, Fairbanks and Nazel hammers

Wildrose Little Giant Video Sold in the

U.S. exclusively by

anvilfire.com

S T R I K E R Self contained pneumatic forging

hammers.

Pounding out the Profits Book Review

LITTLE GIANT Specs Little Giant Specifications

and prices for all models in 1976

LITTLE GIANT Motors Little Giant Motor selection

graph (reverse engineering)

LITTLE GIANT Images Little Giant and Meyer

Brothers hammer images and commentary.

EC-JYH Supplement Anvilfire NEWS coverage of the

construction of the EC-JYH

ABANA plans for simple air hammer and modified treadle hammer

Air Hammer Parts and Upgrade Kit

Air hammers by Richard Furrer

Brake for a 50lb Little Giant Power Hammer

Building A Kinyon Style Hammer

Die Keys for Little Giant Power Hammers

Frog Valley forge power hammer photos

Helpful ideas for setting up a small air hammer written primarily for the China Power Hammer (STC88), but should be useful to all.

Plans for a simple treadle hammer (PDF)

Plans for Krusty - The Power hammer (PDF)

Plans of the Vernet trip hammer

Power hammer based on the Appalachian Dusty

Rusty: Appalachian power hammer

The Grasshopper treadle hammer Old site's photos are gone, but you can see what one looks like here

The Helve hammer - Theory, Tuning, and Practice

The rebuild process of a Champion 65# power hammer

Treadle Hammer.. Full Picture:

Treadle Hammer - Kit - Hardware - Plans

Treadle hammer plans for sale from Bob Warner

Vibration & noise issues with power hammers

25 Ton Hydraulic Forging Press By Ron Claiborne

Build Your Own Hydraulic Forging Press

Build Your Own Hydraulic Forging Press

Hydraulic press plans for sale from Bob Warner

Imagination Xpress hydraulic forging press

Imagination Xpress hydraulic forging press

Junkyard hydraulic press photo 1:

Junkyard hydraulic press photo 2

Junkyard hydraulic press photo 3

Matt Walker's 30 ton Hydraulic Forging press (,pdf)

Press gallery by D, Fogg

RR track hot cutter for a hydraulic press by D. Fogg

Thread about press forging dynamics

Mill:

Books - Classes - Forums - Heat treat - Miscellaneous - Multiple tutorials - Shop - Single tutorials - Supplies - Videos